What Are Cylinder Sleeves?

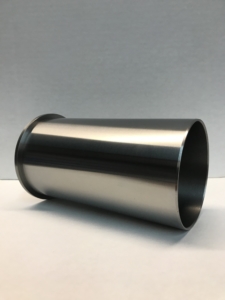

Cylinder sleeves, also known as cylinder liners, are precision-engineered components installed inside an engine block’s cylinder bore.

Their primary purpose is to restore, protect, or enhance the cylinder surface where the piston travels. Cylinder sleeves are commonly used to repair worn or damaged engine blocks, reinforce cylinders in high-stress applications, and extend engine life in both diesel and gasoline engines.

In high-performance, diesel, and heavy-duty engines, cylinder sleeves play a critical role in maintaining structural integrity under extreme heat and pressure. When properly designed and manufactured, they provide a durable wear surface while helping engines perform reliably for hundreds of thousands of cycles.

Why Sleeve An Engine?

We sleeve engines for a couple of reasons. The primary reason for sleeving an engine to either repair a cylinder bore or protect it from damage in the first place.

Sleeves can also be used to restore a particular bore size if a cylinder has to be “bored out” to repair a cracked or otherwise damaged engine. Some engine builders will also “overbore” their cylinders to increase the engine displacement.

Diesel engines are more commonly sleeved than gasoline, but there are reasons to sleeve gas engines as well. High performance diesel engines can produce substantial pressure inside of the bore, so much that damage to cylinders is fairly common. Sleeves intended for high-performance applications can greatly protect the engine from these extreme pressures.

Cylinder sleeves or cylinder liners are often divided into two types: Dry Sleeves and Wet Sleeves. Most aluminum OEM automotive engine blocks use dry, gray iron cylinder sleeves in their engines. A dry sleeve is either cast into or press fit into the bore of the block. The aluminum bore transfers heat from the sleeve to the coolant contacting the bore.

Simply put, a dry sleeve does not contact the coolant. Rather, it is installed into the wall of the cooling jacket in the cylinder block. By contrast, in a wet sleeve coolant comes in direct contact with the sleeve. Dry sleeves also tend to have thin walls as compared with wet sleeves.

Wet sleeves often have a cooling water gap between the engine block and liner. They also can be manufactured to incorporate cooling passages. Sleeves with cooling passages can also be known as water-jacket sleeves.

Due to being in direct contact with the coolant, wet sleeved cylinders have better cooling and a more even temperature distribution, but this design makes the engine as a whole less rigid.

Cylinder Sleeve Vs. Cylinder Liner

If you are looking to rebuild your high-performance engine and you hear the term cylinder sleeve and then cylinder liner and you are wondering what the difference here you go.

The terms cylinder sleeve and cylinder liner are used interchangeably. Both refer to a removable or replaceable cylinder wall installed within the engine block. While the terminology may vary by industry or region, the function remains the same: to provide a durable, precisely machined surface for piston operation while protecting the engine block itself.

How Cylinder Sleeves Promote Engine Longevity

Cylinder sleeves help extend engine life by protecting the engine block from wear, heat, and mechanical stress. The cylinder bore is exposed to constant friction, high combustion pressures, and repeated thermal cycles, all of which can gradually degrade the cylinder wall and reduce engine performance.

By providing a dedicated wear surface, cylinder sleeves absorb this damage instead of the engine block itself. This helps prevent permanent block damage and allows engines to be rebuilt rather than replaced. Maintaining proper bore geometry also supports consistent piston ring sealing, compression, and oil control over time.

In demanding applications, cylinder sleeves reinforce the cylinder bore against distortion, fatigue, and cracking caused by extreme operating conditions. Rather than serving only as a repair solution, cylinder sleeves are often used as a proactive measure to improve durability, reliability, and long-term engine longevity.